All Blogs

-

Hassle free fuel management service

Best Metal Fabricator at fastengineers

Peso License Consultant

Find your Solutions with fast engineers and fabricators

BEST GASOLINE SERVICE STATION

Know About Types Of Fuels With Fast Engineers and Fabricators

AREAS OF WORK OF PESO License Consultant

DIFFERENT TYPES OF MANIFOLDS

BEST SERVICES OF Fast Engineers and Fabrications

WHAT ARE Manifold Fastengineers

Oil and Petroleum Storage Tanks

Various Processes Of Metal Fabrication

INSIGHT ABOUT METAL FABRICATION

Requirement Of Explosive License at Fast Engineers

CONSULTANT SERVICE PROVIDER in Fast Engineers Service

THE BEST ENGINEERING SERVICES IS JUST ONE CLICK AWAY

Avail Best Gas Dispensers

DIFFERENT TYPES OF STORAGE TANKS FOR OIL AND PETROLEUM

COMPONENTS AND WORKING OF MANIFOLD SYSTEM

what exactly is metal fabrication

PRODUCTS THAT REQUIRE PESO and Explosive License

REQUIREMENTS OF STORING PETROLEUM

BEST INSTALLATION SERVICE OF UST

HOW FAST ENGINEERS and FABRICATION CAN HELP YOU WITH PESO LICENCE

CONTRACT MANUFACTURING at fastengineers.in

MARKET OVERVIEW OF METAL FABRICATION INDUSTRY

PETROLEUM STORAGE AND IT'S STORAGE LIFE

FIND YOUR STORAGE TANKS FOR OIL AND PETROLEUM

INSIGHT ABOUT PETROLEUM

WHY CHOOSE FAST ENGINEERS & FABRICATORS

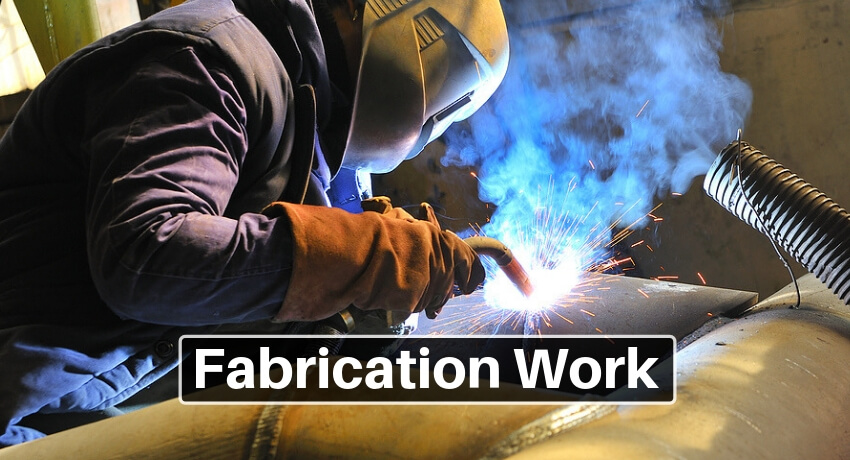

WELDING AND FABRICATION at fastengineers.in

Types of Fabrication Services at Fastengineers

Cutting:-

The first and the most commonly used fabrication method is Cutting which includes cutting of a metal workpiece is a common fabrication technique in which the material is cut into smaller sections.Modern techniques involving state-of-the-art machinery are used now which has almost replaced the old days of sawing methods. The tools and techniques used now include laser cutting, waterjet cutting, power scissors, and plasma arc cutting.

Forming:-

Other than cutting, forming holds an important place when it comes to the types of fabrication and it includes the process that bends or distorts metal to produce parts and components. To shape the workpiece into the desired form, Strips or sheets of metal are continuously fed through parallel rollers and during the process of forming, the metal material does not lose its mass, only its form.

Shearing

Third method that we have here is Shearing which is used to trim unwanted material from metal material, shearing is achieved by mounting two blades above and beneath the metal to produce one long, straight cut. This method is commonly used to cut smaller lengths and differently shaped materials, the blades can be mounted at angles to reduce the necessary shearing force required. If one wants straight cuts, then they are achieved by combining two tools, essentially blades, with one of the tools above the metal and the other one located below for applying pressure. In such cases, the upper blade forces the metal down onto the fixed or stationary lower blade to fracture the piece and complete the separation.

Welding:-

A yet another commonly used method is welding which is considered as an art of joining two or more pieces of metal together utilizing a combination of heat and pressure. There are majorly three types of welding procedures including Stick or Arc Welding, MIG Welding, and TIG Welding.

Stamping:-

As its name defines, it creates an indentation rather than a hole during fabrication. The turret presses against the metal forcing the die to stamp shapes, letters, or images into the metal workpiece in various sizes and shapes.

Punching:-

Punch presses are mechanical devices used to punch or create holes in metals. Punching has a two-fold purpose - A punch press houses turrets that strike metal through and the result “punches” or creates uniquely designed holes in the metal. The resultant product can either be the removed uniquely shaped pieces that were punched out from the metal, known as blanks, or the holes can be used for fastening purposes.

Fast Engineers & Fabricators are one of the renowned Fabricators Service India, Petroleum storage tanks, Fabrication Service. To avail its services - Contact Fast Engineers & Fabricators